Let’s dive into the world of construction safety guidelines, where precaution meets precision in every building endeavor. From identifying common hazards to outlining key safety measures, this topic is a must-read for anyone stepping foot on a construction site.

In the realm of construction, safety isn’t just a checklist—it’s a mindset that shapes the very foundation of every project. Join us as we explore the crucial elements of maintaining a secure and protected work environment in the construction industry.

Construction Safety Guidelines

Construction sites can be dangerous places if proper safety guidelines are not followed. It is crucial for all workers to adhere to safety protocols to prevent accidents and injuries.

Common Safety Hazards in the Construction Industry

- Working at heights without proper fall protection

- Electrical hazards

- Unsafe use of machinery and equipment

- Scaffold collapse

- Slips, trips, and falls

Role of Personal Protective Equipment (PPE) in Ensuring Construction Safety

Personal Protective Equipment (PPE) plays a vital role in keeping workers safe on construction sites. It includes items such as hard hats, safety goggles, gloves, and steel-toed boots. PPE helps protect workers from various hazards like falling objects, sharp materials, and chemical exposure.

Key Safety Guidelines for Working at Heights in Construction

- Always wear proper fall protection gear, including harnesses and lanyards.

- Inspect fall protection equipment regularly for any signs of wear or damage.

- Never work on elevated surfaces if you are feeling dizzy, fatigued, or under the influence of drugs or alcohol.

- Ensure that guardrails, safety nets, or other protective measures are in place when working at heights.

- Receive proper training on how to use fall protection equipment correctly.

Chemicals and Allied Products

When working on a construction site, handling chemicals can pose serious hazards if not done properly. It is crucial to understand the potential risks associated with these substances and follow strict safety protocols to protect yourself and others.

Potential Hazards of Handling Chemicals

- Exposure to toxic fumes or vapors

- Skin irritation or burns

- Fire and explosion risks

- Potential for chemical spills or leaks

- Risk of contamination if not handled correctly

Proper Storage and Handling Procedures for Chemicals

Chemicals should be stored in a designated area away from heat sources and incompatible materials. They must be properly labeled, and only trained personnel should handle them. Spill containment measures should be in place, and all containers must be tightly sealed when not in use.

Importance of Safety Data Sheets (SDS)

- SDS provide crucial information about the hazards of a chemical, proper handling procedures, and emergency response measures.

- Workers should be trained to read and understand SDS to prevent accidents and injuries.

- SDS must be readily accessible to all employees working with chemicals on the construction site.

Types of Personal Protective Equipment (PPE) for Chemical Handling

When working with chemicals, it is essential to wear the appropriate PPE to minimize exposure and reduce the risk of accidents. This may include protective gloves, goggles, face shields, respirators, and chemical-resistant clothing.

Construction and Maintenance

Construction and maintenance activities in the workplace require specific safety guidelines to ensure the well-being of workers and prevent accidents. While there are some overlapping safety measures between construction and maintenance, it is essential to differentiate between the two to address their unique risks and hazards effectively.

Differentiating Safety Guidelines

- Construction: Safety guidelines for construction focus on initial site preparation, structural work, and installation of building components. This includes measures such as fall protection, scaffolding safety, and equipment inspection.

- Maintenance: On the other hand, maintenance safety guidelines pertain to ongoing upkeep, repair, and inspection of existing structures. This may involve electrical maintenance, plumbing repairs, and HVAC system checks.

Preventative Maintenance Measures

- Regular equipment inspections and maintenance schedules can prevent unexpected breakdowns and accidents.

- Implementing a routine cleaning and repair program for building components can enhance their longevity and safety.

- Training employees on proper maintenance procedures and safety protocols is essential to avoid workplace injuries.

Significance of Regular Inspections

Regular inspections play a crucial role in ensuring safety during construction and maintenance activities. By identifying potential hazards early on, inspections help mitigate risks and prevent accidents. Inspections also ensure that safety protocols are being followed and that equipment is in good working condition.

Creating a Safety Plan

- Assess the specific risks associated with the construction or maintenance project, considering factors like the type of work, equipment involved, and environmental conditions.

- Establish clear safety objectives and protocols that address identified risks, outlining procedures for hazard mitigation and emergency response.

- Train all employees and contractors on the safety plan, ensuring they understand their roles and responsibilities in maintaining a safe work environment.

Consumer Goods and Services

Construction safety guidelines play a crucial role in ensuring the quality and safety of consumer goods and services. By adhering to these guidelines, companies can mitigate risks and prevent accidents that could potentially harm consumers during construction projects.

Impact on Consumer Safety

- Implementing safety guidelines in construction projects directly impacts the quality of consumer goods and services by ensuring that they are built to code and meet safety standards.

- By prioritizing safety, companies can reduce the likelihood of accidents or defects that could harm consumers, thereby enhancing trust and confidence in their products and services.

- Consumer safety is paramount in the construction industry, and following safety guidelines is not only a legal requirement but also an ethical responsibility towards the end-users of the products and services.

Best Practices for Ensuring Consumer Safety

- Conduct thorough risk assessments before starting any construction project to identify potential hazards and implement appropriate safety measures.

- Regularly train employees on safety protocols and provide them with the necessary protective equipment to prevent accidents and injuries.

- Engage with consumers and stakeholders to gather feedback on safety concerns and make necessary improvements to ensure their well-being.

Role of Regulatory Bodies

- Regulatory bodies play a crucial role in monitoring and enforcing construction safety standards to protect consumers from potential risks and ensure compliance with regulations.

- These bodies conduct inspections, issue permits, and impose penalties on companies that fail to meet safety requirements, thereby holding them accountable for the safety of consumers.

- By working closely with regulatory bodies, companies can stay updated on the latest safety regulations and guidelines to maintain high standards of consumer safety in their construction projects.

Enhancing Consumer Trust through Safety Guidelines

- Implementing safety guidelines not only protects consumers from harm but also builds trust and credibility for companies in the construction industry.

- Consumers are more likely to choose companies that prioritize safety and demonstrate a commitment to ensuring their well-being throughout the construction process.

- By showcasing a strong adherence to safety standards and regulations, companies can differentiate themselves in the market and establish a reputation for reliability and quality in delivering consumer goods and services.

Business Energy

When it comes to business energy, following construction safety guidelines is crucial for ensuring not only the well-being of workers but also for promoting energy efficiency in businesses. By integrating safety measures into construction practices, companies can reduce energy-related accidents and improve overall operational efficiency.

Correlation between Safety Guidelines and Energy Efficiency

- Implementing proper safety protocols can lead to a more organized work environment, reducing the risk of accidents that may result in energy wastage or equipment damage.

- Regular safety inspections and maintenance can help identify and address potential energy leaks or inefficiencies in machinery and equipment.

- Training employees on safety procedures can increase awareness about energy-saving practices and encourage a culture of efficiency within the organization.

Impact on Reducing Energy-Related Accidents

- Adhering to safety guidelines can prevent workplace incidents that may lead to electrical malfunctions, fires, or other energy-related accidents.

- Proper storage and handling of hazardous materials can minimize the risk of spills or leaks that could result in energy wastage or environmental harm.

- Ensuring proper ventilation and air quality control can improve energy efficiency by optimizing heating, cooling, and ventilation systems.

Energy-Efficient Construction Practices

- Utilizing energy-efficient lighting systems, such as LEDs, and implementing motion sensors to reduce unnecessary energy consumption.

- Installing insulation and energy-efficient windows to improve thermal performance and reduce heating and cooling costs.

- Incorporating renewable energy sources, such as solar panels or wind turbines, to supplement traditional energy sources and reduce carbon footprint.

Case Studies of Successful Integration

- Company A implemented a comprehensive safety training program that included energy-saving practices, resulting in a 20% reduction in energy consumption within the first year.

- Company B conducted regular safety audits that identified energy inefficiencies in their production line, leading to the implementation of new equipment and processes that reduced energy costs by 15%.

- Company C established a safety committee that focused on energy management strategies, resulting in improved safety protocols and a 25% decrease in energy-related incidents.

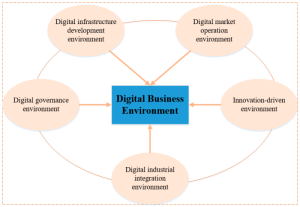

Business Environment

Adhering to construction safety guidelines is crucial for creating a positive work environment within a business. By prioritizing safety, businesses can foster a culture of well-being and care for their employees, leading to increased job satisfaction and loyalty.

Financial Benefits for Businesses

- Reduced insurance costs due to fewer workplace accidents and injuries.

- Lower expenses related to worker compensation claims and legal fees.

- Increased productivity and efficiency resulting from a safe work environment.

Risks to Business Reputation

- Negative publicity and public perception if safety violations are uncovered.

- Potential loss of clients or contracts due to a reputation for disregarding safety protocols.

- Damage to brand image and trust among stakeholders.

Influence on Employee Productivity and Morale

A safe work environment directly impacts employee productivity and morale by:

- Increasing employee satisfaction and motivation to perform well.

- Reducing absenteeism and turnover rates.

- Promoting a positive company culture and teamwork among employees.

Wrap-Up

As we wrap up our discussion on construction safety guidelines, remember that safety isn’t an option—it’s a necessity. By adhering to these guidelines, we pave the way for a future where every construction project is not only a masterpiece of architecture but also a testament to unwavering commitment to safety.

FAQ Overview

What are the common safety hazards in the construction industry?

Common safety hazards in construction include falls from heights, electrical hazards, scaffold collapses, and accidents involving heavy machinery.

How does personal protective equipment (PPE) ensure construction safety?

PPE such as hard hats, gloves, safety glasses, and boots protect workers from injuries and reduce the risk of accidents on construction sites.

Why is it important to have a safety plan for construction projects?

A safety plan Artikels procedures to prevent accidents, respond to emergencies, and ensure the well-being of workers throughout the construction process.