Chemicals used in renewable energy sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail with entertaining interactive style and brimming with originality from the outset.

From solar energy systems to wind turbine construction and biofuel production, the world of renewable energy is powered by a fascinating array of chemicals, each playing a vital role in shaping a sustainable future.

Chemicals used in Renewable Energy

Chemicals play a crucial role in the production of renewable energy, contributing to the efficiency and sustainability of various systems. From solar energy to wind turbines and biofuels, specialized chemicals are essential in harnessing clean energy sources.

Solar Energy Systems

- Silicon: Silicon is a key component in solar panels, helping to convert sunlight into electricity through photovoltaic cells.

- Cadmium Telluride: Another common chemical used in thin-film solar panels, offering a cost-effective alternative to traditional silicon panels.

- Copper Indium Gallium Selenide (CIGS): CIGS solar cells use this compound to absorb sunlight efficiently and generate electricity.

Wind Turbine Construction

Specialized chemicals are essential in the construction of wind turbines, ensuring durability and performance in generating wind energy.

- Epoxy Resins: Used to bond and protect the components of wind turbine blades, enhancing their strength and longevity.

- Fiberglass: Provides reinforcement and lightweight properties to wind turbine blades, improving their aerodynamic efficiency.

- Polyurethane Coatings: Applied to wind turbine surfaces to protect against corrosion and harsh environmental conditions.

Biofuel Production

Chemical processes are involved in the production of biofuels, transforming organic materials into a sustainable energy source.

- Transesterification: This chemical process converts vegetable oils or animal fats into biodiesel, a renewable alternative to traditional fossil fuels.

- Fermentation: Used in the production of bioethanol from sugars or starches, providing a clean and renewable fuel for transportation.

- Hydrogenation: Converts oils and fats into biodegradable diesel fuel, contributing to reducing greenhouse gas emissions.

Chemicals and Allied Products

Chemicals and allied products play a crucial role in various industries, including renewable energy. Allied products are a broad category that includes chemicals used in conjunction with primary chemicals for specific applications.

Types of Allied Products

Allied products encompass a range of chemicals such as catalysts, solvents, additives, and stabilizers. These chemicals are often used in combination with primary chemicals to enhance performance, increase efficiency, or achieve specific properties in the final product.

Usage in Renewable Energy vs. Other Industries

In renewable energy, chemicals are used in processes like solar panel manufacturing, battery production, and biofuel refinement. The usage of chemicals in renewable energy differs from other industries in terms of environmental considerations and sustainability goals. While some industries prioritize cost-effectiveness and production efficiency, the renewable energy sector focuses on minimizing environmental impact and promoting clean energy solutions.

Significance of Quality Control

Quality control is essential in chemical production to ensure the consistency and reliability of the end products. In industries like renewable energy, where the performance and longevity of components are crucial, maintaining high-quality standards in chemical production is paramount. Quality control measures help prevent defects, ensure product safety, and uphold industry regulations.

Environmental Impact of Chemical Waste Disposal

The disposal of chemical waste from allied products manufacturing can have significant environmental consequences if not managed properly. Improper disposal methods can lead to soil and water contamination, air pollution, and harm to ecosystems. It is essential for companies to implement proper waste management practices, such as recycling, treatment, and disposal in approved facilities, to minimize the environmental impact of chemical waste.

Construction and Maintenance

Solar panels are a crucial component of renewable energy systems, harnessing sunlight to generate electricity. The construction and maintenance of solar panels require specific chemicals to ensure their efficiency and longevity.

Chemicals for Solar Panel Construction

- Silicon: Silicon is a key material used in the production of solar panels, as it is the main component of solar cells that capture sunlight and convert it into electricity.

- Silver Paste: Silver paste is used to create electrical connections within the solar cells, allowing the flow of electricity produced by sunlight.

- Ethylenediaminetetraacetic Acid (EDTA): EDTA is used in the cleaning process of solar panels to remove contaminants and maintain their performance.

Geothermal Energy Plant Construction Process

Geothermal energy plants utilize the Earth’s heat to generate electricity. Here is a step-by-step guide on how chemicals are used in their construction:

- Drilling Fluids: Chemicals such as bentonite, polymers, and acids are used as drilling fluids to help with the drilling process to reach geothermal reservoirs.

- Corrosion Inhibitors: Corrosion inhibitors are applied to prevent the deterioration of equipment and piping due to the high temperatures and corrosive nature of geothermal fluids.

- Scale Inhibitors: Scale inhibitors are used to prevent the build-up of mineral deposits inside the geothermal wells and equipment, ensuring efficient operation.

Maintenance of Offshore Wind Farms

Offshore wind farms require regular maintenance to ensure optimal performance and longevity. Here are the maintenance procedures involving chemicals for offshore wind farms:

- Antifouling Coatings: Antifouling coatings are applied to the turbine blades to prevent the accumulation of marine organisms, such as algae and barnacles, which can reduce efficiency.

- Corrosion Protection: Corrosion protection coatings are used on the metal components of offshore wind turbines to prevent rust and deterioration caused by exposure to saltwater.

- Lubricants: Specialized lubricants are used in the maintenance of offshore wind turbines to ensure smooth operation and reduce friction in moving parts.

Challenges of Handling Hazardous Chemicals

Handling hazardous chemicals in renewable energy infrastructure upkeep poses unique challenges, including:

Ensuring proper storage and disposal of hazardous chemicals to prevent environmental contamination.

Providing adequate training and protective gear for workers to minimize risks associated with handling dangerous chemicals.

Implementing strict safety protocols and emergency response plans in case of chemical spills or accidents during maintenance activities.

Consumer Goods and Services

Consumer demand for eco-friendly chemicals used in renewable energy products is on the rise as more individuals become conscious of the environmental impact of their purchases. This shift towards sustainable options is influencing the market and driving companies to innovate in their product offerings.

Market Demand for Eco-friendly Chemicals

- Consumers are seeking energy-efficient appliances and consumer goods that are made using green chemicals to reduce their carbon footprint.

- Companies are responding to this demand by increasing the use of sustainable chemicals in their products, promoting a healthier environment.

- The market for eco-friendly chemicals in consumer goods related to renewable energy is expected to grow as awareness of sustainability issues continues to spread.

Regulations and Safety

- Regulations play a crucial role in ensuring the safety of chemicals used in consumer goods related to renewable energy, protecting both consumers and the environment.

- Government agencies set standards for the use of green chemicals, monitoring their impact on health and the environment to prevent any harmful effects.

- Compliance with regulations is essential for consumer goods companies to maintain trust and credibility with their customers.

Innovative Incorporation of Green Chemicals

- Consumer goods companies are finding innovative ways to incorporate green chemicals into their product lines, offering sustainable alternatives to traditional options.

- From energy-efficient appliances to eco-friendly cleaning products, these companies are prioritizing environmental responsibility in their manufacturing processes.

- By embracing green chemistry principles, consumer goods companies can differentiate themselves in the market and attract eco-conscious consumers.

Business Energy

Businesses are increasingly turning to chemical innovations to enhance renewable energy production. By leveraging specialized chemicals, companies can improve the efficiency and reliability of their energy projects, ultimately contributing to a more sustainable future.

Cost Implications of Specialized Chemicals in Large-Scale Energy Projects

Using specialized chemicals in large-scale energy projects can have significant cost implications. While these chemicals may come with a higher upfront cost, their ability to optimize energy production and reduce maintenance expenses can result in long-term savings for businesses. It is crucial for companies to carefully evaluate the cost-benefit analysis of incorporating these chemicals into their energy operations.

Partnerships Between Chemical Companies and Energy Firms

Collaborations between chemical companies and energy firms play a crucial role in driving innovation in the renewable energy sector. By combining expertise and resources, these partnerships enable the development of new technologies that can enhance energy production efficiency and sustainability. Through strategic alliances, companies can accelerate the adoption of chemical solutions that benefit both the environment and their bottom line.

Potential for Chemical Recycling in the Renewable Energy Sector

Chemical recycling holds great promise for reducing waste and costs in the renewable energy sector. By reusing and repurposing chemicals from end-of-life products or byproducts, companies can minimize their environmental footprint and promote circular economy principles. Implementing chemical recycling initiatives can not only drive cost savings but also contribute to a more sustainable energy ecosystem.

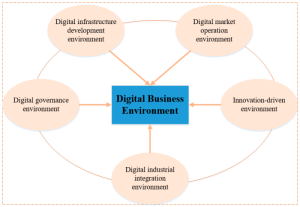

Business Environment

In the business environment, the use of chemicals in renewable energy has a significant impact on operations and decision-making processes.

Impact of Chemicals in Renewable Energy

- Chemicals used in renewable energy can affect the overall cost and efficiency of energy production.

- Businesses need to consider the environmental impact of these chemicals on their operations and reputation.

- Regulatory compliance and sustainability goals play a crucial role in shaping business strategies in the energy sector.

Sustainability Practices and Business Decisions

- Companies that prioritize sustainability practices related to chemicals are more likely to attract environmentally conscious consumers and investors.

- Investing in green chemical solutions can lead to long-term cost savings and competitive advantages in the market.

- Businesses that incorporate sustainability into their operations are better positioned to adapt to changing regulations and consumer preferences.

Challenges in Sourcing Environmentally Friendly Chemicals

- Finding reliable suppliers of environmentally friendly chemicals for renewable energy projects can be challenging due to limited availability and higher costs.

- Businesses may face compatibility issues with existing infrastructure when transitioning to greener chemical solutions.

- Educating employees and stakeholders about the benefits of using eco-friendly chemicals is essential for successful implementation.

Companies Leading the Way in Green Chemical Solutions

- Company A has invested in research and development to create sustainable chemical alternatives for their energy production processes.

- Company B has implemented a comprehensive sustainability strategy that includes the use of green chemicals in all aspects of their operations.

- Company C has formed partnerships with environmentally conscious suppliers to ensure a steady and reliable source of eco-friendly chemicals for their renewable energy projects.

Ultimate Conclusion

As we conclude this exploration of chemicals used in renewable energy, it’s clear that these innovative solutions not only drive environmental progress but also pave the way for a greener, cleaner future powered by sustainable practices and cutting-edge technologies.

Query Resolution

What types of chemicals are commonly used in solar energy systems?

Chemicals like silicon, cadmium telluride, and copper indium gallium selenide are often used in solar panels to capture and convert sunlight into electricity.

How do specialized chemicals contribute to wind turbine construction?

Specialized chemicals are crucial for creating durable materials like composites and coatings that withstand harsh environmental conditions, enhancing the efficiency and longevity of wind turbines.

What role do regulations play in ensuring the safety of chemicals used in renewable energy consumer goods?

Regulations help enforce quality control standards, ensuring that eco-friendly chemicals used in consumer goods related to renewable energy meet safety and environmental criteria.