Step into the world where concrete meets chemicals in the construction industry, unveiling a realm of innovation and necessity. From foundation to finish, let’s explore the crucial role of chemicals in shaping our built environment.

Delve deeper into the realm of construction as we unravel the mysteries behind the use of various chemicals in every stage of the building process.

Chemicals in Construction Industry

Chemicals play a crucial role in the construction industry, aiding in various processes to enhance durability, strength, and overall quality of structures. From concrete production to waterproofing, chemicals are essential components in modern construction practices.

Types of Chemicals Used in Construction

- Admixtures: These chemicals are added to concrete to improve workability, strength, and durability.

- Waterproofing Compounds: Used to protect structures from water damage and increase their lifespan.

- Sealants and Adhesives: Essential for bonding materials together and sealing gaps in structures.

- Protective Coatings: Applied to surfaces to provide protection against corrosion, weathering, and chemical exposure.

Importance of Chemical Usage in Construction Processes

Chemicals are vital in construction for several reasons:

- Enhancing Strength: Admixtures improve the strength and durability of concrete, making structures more resilient.

- Waterproofing: Waterproofing compounds prevent water infiltration, protecting buildings from moisture-related damage.

- Corrosion Protection: Protective coatings shield metal structures from corrosion, extending their lifespan.

- Improving Aesthetics: Sealants and adhesives help achieve a polished finish and enhance the appearance of structures.

Chemicals and Allied Products

Chemicals play a crucial role in the construction industry, providing essential materials for various processes and applications. In this section, we will explore the comparison of chemicals used in construction with those in other industries, the significance of quality control in chemical manufacturing for the construction sector, and the environmental impact of chemicals and allied products on the construction industry.

Comparison of Chemicals in Construction and Other Industries

Chemicals used in construction differ from those in other industries due to their specific functions and requirements. For example, in the construction sector, chemicals are often used for bonding materials, waterproofing, and enhancing durability. On the other hand, chemicals in industries like pharmaceuticals or agriculture serve different purposes such as drug synthesis or crop protection.

Significance of Quality Control in Chemical Manufacturing for Construction

Quality control in chemical manufacturing is crucial for the construction industry to ensure the reliability and performance of construction materials. Consistent quality standards help in maintaining the structural integrity of buildings and infrastructure, reducing the risk of failures or hazards. It also enhances the overall efficiency and longevity of construction projects.

Environmental Impact of Chemicals in Construction Industry

The environmental impact of chemicals and allied products in the construction industry is a growing concern. Chemicals used in construction processes can contribute to pollution, resource depletion, and ecosystem disruption. It is essential for construction companies to adopt sustainable practices, such as using eco-friendly materials and minimizing chemical waste, to mitigate the environmental impact and promote a greener construction industry.

Construction and Maintenance

Chemicals play a vital role in the construction and maintenance of infrastructure, providing solutions for various tasks such as bonding, sealing, and protecting materials. They are essential for enhancing the durability and performance of structures.

Chemical Applications in Maintenance

- Adhesives and Sealants: Chemical adhesives are used to bond materials together, while sealants help prevent water infiltration and air leakage, maintaining the integrity of structures.

- Concrete Repair: Chemical compounds are utilized to repair cracks, spalls, and other damages in concrete structures, extending their lifespan.

- Protective Coatings: Chemical coatings are applied to surfaces to protect them from corrosion, UV rays, and chemical exposure, ensuring longevity.

Challenges and Safety Considerations

- Proper Handling and Storage: Chemicals must be stored and handled safely to prevent accidents and exposure to hazardous substances.

- Environmental Impact: The disposal of chemical waste from construction and maintenance activities can have detrimental effects on the environment if not managed properly.

- Worker Safety: Workers must be trained on the safe use of chemicals, including wearing protective gear and following proper protocols to minimize health risks.

Consumer Goods and Services

Consumer goods and services play a crucial role in the construction industry, as they are directly impacted by the use of chemicals in various construction projects. The demand for specific consumer goods and services often drives the selection and application of certain chemicals in construction processes.

Impact on Consumer Goods

- Chemicals used in construction, such as adhesives, sealants, and coatings, can directly influence the quality and durability of consumer goods like furniture, flooring, and fixtures.

- The use of environmentally friendly chemicals in construction can lead to the production of sustainable consumer goods, aligning with the increasing demand for eco-friendly products.

- Chemicals that enhance fire resistance or water repellency in construction materials contribute to the safety and longevity of consumer goods and services.

Link between Consumer Demands and Chemical Use

- Consumer preferences for stylish, durable, and sustainable products drive the development and use of advanced chemicals in construction to meet these demands.

- As consumers become more conscious of health and environmental impacts, the construction industry adapts by utilizing non-toxic chemicals in the production of consumer goods and services.

- The customization and personalization trend in consumer goods are supported by the versatility of chemicals used in construction, allowing for unique and innovative designs.

Innovations in Chemical Use for Enhanced Consumer Goods

- Advancements in nanotechnology have led to the development of nano-coatings and materials that improve the performance and aesthetics of consumer goods in construction.

- The integration of smart chemicals and materials in construction enhances the functionality and connectivity of consumer goods, offering new levels of convenience and efficiency.

- Collaborations between chemical manufacturers and consumer goods companies result in the creation of specialized formulations that cater to specific needs and preferences of consumers.

Business Energy

In the construction industry, the production of chemicals plays a crucial role in creating various materials and products used in building projects. The manufacturing of these chemicals requires a significant amount of energy, which can have implications for both the environment and the construction sector as a whole.

Energy Requirements for Chemical Production

- Chemical production for construction involves processes such as synthesis, purification, and packaging, all of which require energy inputs.

- The energy sources used for chemical production can vary, including electricity, natural gas, and fossil fuels.

- Some chemical reactions in the manufacturing process may also require specific temperature and pressure conditions, further increasing energy consumption.

Trends in Sourcing Energy for Chemical Production

- There is a growing trend towards using renewable energy sources, such as solar or wind power, to reduce the environmental impact of chemical production.

- Companies are also exploring energy-efficient technologies and processes to optimize their production methods and minimize energy consumption.

- Collaborations with energy providers and government initiatives promoting sustainable energy use are becoming more common in the chemical manufacturing sector.

Implications of Energy Consumption in Chemical Manufacturing for Construction

- The energy-intensive nature of chemical production can lead to higher production costs, which may ultimately affect the pricing of construction materials.

- Increased energy consumption can contribute to greenhouse gas emissions and other environmental concerns, impacting the overall sustainability of construction projects.

- Efforts to reduce energy consumption in chemical manufacturing can lead to innovations in green chemistry and the development of more eco-friendly construction materials.

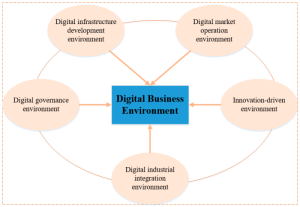

Business Environment

The business environment surrounding the use of chemicals in the construction industry is heavily influenced by regulatory policies and environmental concerns. Businesses in this sector must navigate a complex landscape of rules and standards to ensure the safe and responsible use of chemicals in their operations.

Regulatory Landscape

The regulatory landscape governing the use of chemicals in the construction industry is vast and constantly evolving. Government agencies such as the Environmental Protection Agency (EPA) and Occupational Safety and Health Administration (OSHA) set guidelines and standards to protect workers, the public, and the environment from the harmful effects of chemical exposure. Companies in the construction sector must stay up-to-date with these regulations to remain compliant and avoid costly penalties.

Adaptation to Environmental Policies

Businesses in the construction sector are increasingly adapting to changing environmental policies related to chemicals by implementing sustainable practices and investing in green technologies. This includes using eco-friendly building materials, reducing waste and emissions, and implementing energy-efficient construction methods. By embracing these changes, companies can not only meet regulatory requirements but also appeal to environmentally conscious consumers and stakeholders.

Sustainable Practices and Innovations

To create a greener business environment, construction companies are exploring sustainable practices and innovations in chemical usage. This includes the development of bio-based chemicals, non-toxic alternatives, and recycling programs for chemical waste. By incorporating these practices into their operations, businesses can reduce their environmental footprint, improve their reputation, and contribute to a more sustainable future for the construction industry.

Ending Remarks

As we wrap up this journey through the intricate world of chemicals in construction, remember that every structure stands as a testament to the blend of science and craftsmanship. The next time you see a building rise, appreciate the chemical magic that made it all possible.

Top FAQs

How do chemicals contribute to the construction industry?

Chemicals play a vital role in enhancing the properties of building materials, aiding in construction processes like bonding, sealing, and finishing.

What are some common types of chemicals used in construction?

Common chemicals include adhesives, sealants, concrete additives, and waterproofing agents, each serving specific purposes in construction.

How do environmental concerns impact the use of chemicals in construction?

Environmental impact is a crucial consideration, leading to the development of eco-friendly alternatives and sustainable practices in chemical usage for construction.

Why is quality control important in chemical manufacturing for the construction sector?

Quality control ensures that chemicals meet industry standards, guaranteeing safety, reliability, and performance in construction applications.